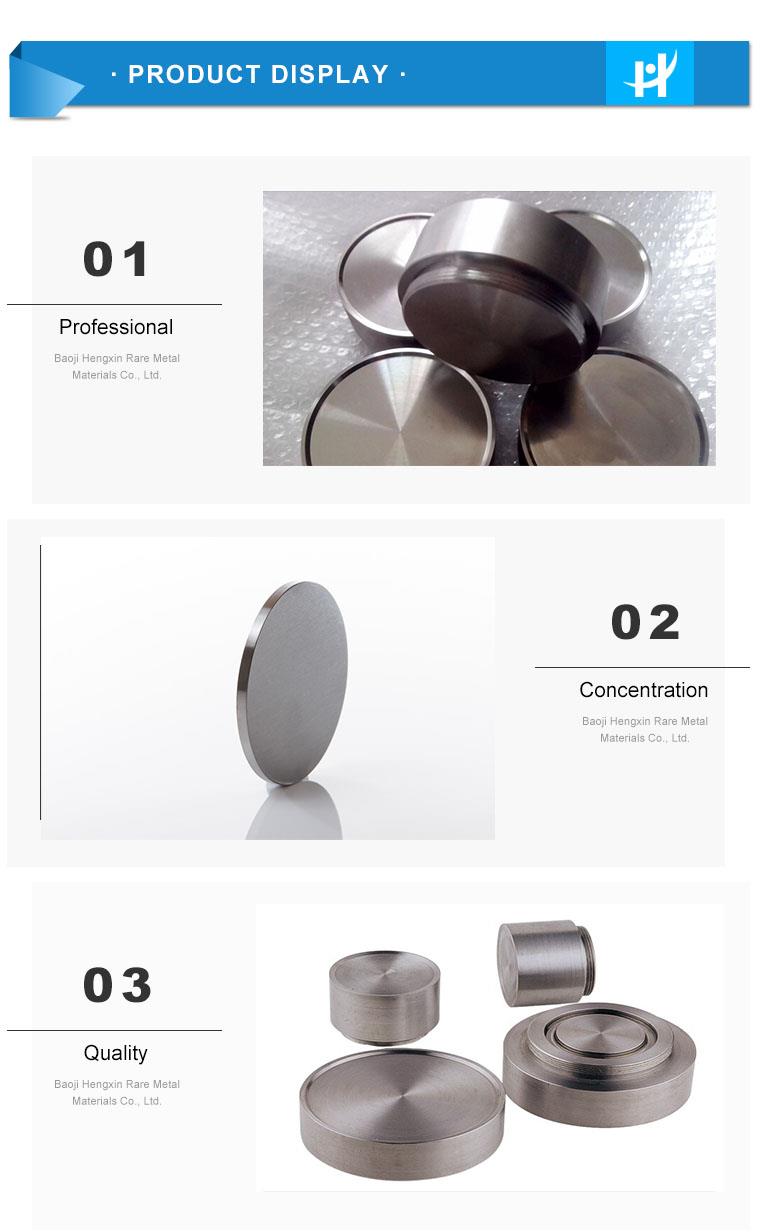

Introduction to Molybdenum Sputtering Target

Molybdenum sputtering target is crucial components in thin film deposition processes, widely used in semiconductor, solar cell, and display industries. These targets are meticulously engineered from high-purity molybdenum, ensuring exceptional performance and reliability in various vacuum deposition systems. With its superior thermal conductivity, excellent mechanical properties, and chemical stability, it facilitates precise and uniform film deposition, enabling the production of advanced electronic devices with enhanced performance.

Product Standards: Molybdenum sputtering target adheres to stringent quality standards to meet the exacting requirements of modern manufacturing processes. Key parameters such as purity, grain size, density, and dimensions are meticulously controlled to ensure consistent performance and compatibility with diverse sputtering systems.

Basic Parameters:

Below is a table outlining the basic parameter standards of our products:

Product Name | molybdenum sputtering target |

Material | Pure molybdenum 99.9%,99.95%,99.99% |

Size | customized |

Working temperature | Around 1700℃ |

Advantages | Good electrical conductivity, thermal conductivity, high temperature resistance |

shapes | made according to drawing |

surface | Mirror bright |

Applications | Conductive glass, STN/TN/TFT-LCD, optical glass, ion coating, etc., suitable for all flat coating and spin coating systems |

Product Attributes:

High Purity: ≥ 99.95% purity ensures minimal impurities for reliable thin film deposition.

Excellent Thermal Conductivity: Facilitates efficient heat dissipation during the sputtering process, minimizing substrate heating.

Superior Mechanical Properties: Withstand rigorous sputtering conditions, ensuring prolonged target life and consistent performance.

Chemical Stability: Resistant to oxidation and corrosion, ensuring stable operation in various process environments.

Product Functions:

Thin Film Deposition: The products are used to deposit thin films of molybdenum onto various substrates through a physical vapor deposition (PVD) process known as sputter deposition.

Barrier Layer Formation: They are employed to deposit molybdenum thin films as barrier layers in semiconductor devices, preventing the intermixing of different materials.

Metallization: The sputter deposition of molybdenum thin films from molybdenum sputtering target is essential for metallization processes in the semiconductor industry. These thin films provide conductive pathways and interconnects within semiconductor devices, contributing to their functionality.

Features:

Customizable Dimensions: Tailored to meet specific customer requirements for different deposition systems.

Uniform Grain Structure: Ensures uniform film deposition and consistent film properties across the substrate.

High Yield: Optimized design and purity result in minimal material wastage during the deposition process.

Advantages and Highlights:

Enhanced Deposition Efficiency: High-purity molybdenum ensures high-quality thin film deposition with minimal defects.

Extended Target Life: Superior mechanical properties contribute to prolonged target longevity, reducing downtime and maintenance costs.

Versatile Applications: Reasonable for a large number of uses including semiconductor creation, photovoltaics, and optical coatings.

Application Areas:

Semiconductor industry: They are generally utilized in the semiconductor business for the affidavit of dainty movies in the creation of coordinated circuits (ICs), computer chips, and other electronic parts.

Solar energy: They are utilized in the manufacturing of thin-film solar cells, which convert sunlight into electricity. Molybdenum is much of the time utilized as a back cathode material because of its great conductivity and dependability.

Optical coatings: Molybdenum sputtering target is employed in the production of optical coatings on various substrates. These coatings enhance the performance and durability of optical devices by improving properties like reflectivity, transparency, and hardness.

Decorative coatings: They are used for decorative purposes, such as the deposition of thin films on jewelry, watches, and other luxury items, providing a desirable aesthetic appearance, durability, and resistance to wear.

Conclusion:

In conclusion, our molybdenum sputtering target combines superior quality, reliability, and customization options, making them the ideal choice for demanding thin film deposition applications across various industries. For inquiries or to place an order, please contact us at betty@hx-raremetals.com.

OEM Service:

We offer OEM services to meet specific customer requirements, including custom dimensions, compositions, and packaging solutions tailored to individual application needs.

FAQ:

Q: What is the typical lead time for molybdenum sputtering targets?

A: Lead times vary depending on the specifications and order quantity. Contact our sales team for precise delivery estimates.

Q: Can you provide technical support for target installation and usage?

A: Yes, our group of specialists offers extensive specialized help to guarantee ideal execution and trouble-free operation of our products.

Q: Do you offer volume discounts for bulk orders?

A: Yes, we provide competitive pricing and volume discounts for large quantity orders. Contact us for a personalized quotation.

Manufacturing Capabilities:

We possess a complete production line for tungsten and molybdenum, tantalum and niobium, as well as micron nitinol wire, tungsten wire, micron nitinol tube, titanium tube, and tantalum tube production. Our state-of-the-art facilities ensure the highest quality standards and efficient production processes to meet the diverse needs of our global clientele.

molybdenum sputtering target

Hot Tags: molybdenum sputtering target, China, suppliers, manufacturers, factory, customized, wholesale, price, buy, for sale, Pure Molybdenum Target, Molybdenum Sputtering Target